Characteristics:

Appearance: Black powder

Packing: 25kg per bag in Ton bag with pallet

Percent Carbon:Min. 99 %

Particle Size Range:Size Varies

Applications:

Melt Cover

Oil Recovery Processes

Carbon Brushes & Parts

Seals & Gaskets

Intumescent Fire Retardants

Expandable graphite not only retains the good lubricating properties, high temperature resistance, and corrosion resistance of natural flake graphite, but it also has the unique characteristic of expanding up to several hundred times its original volume when heated above a certain temperature. Therefore, expandable graphite can be made into various fireproof equipment, which are used in the field of fireproofing and flame retardant.

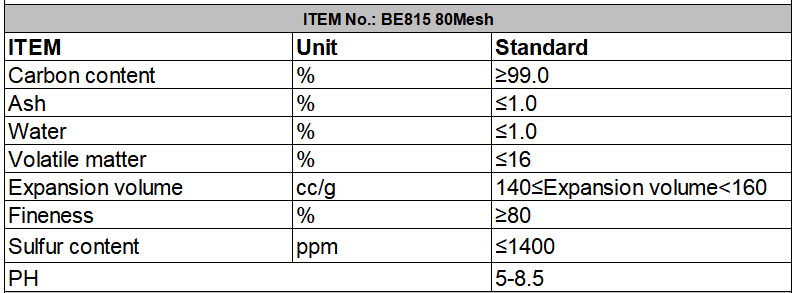

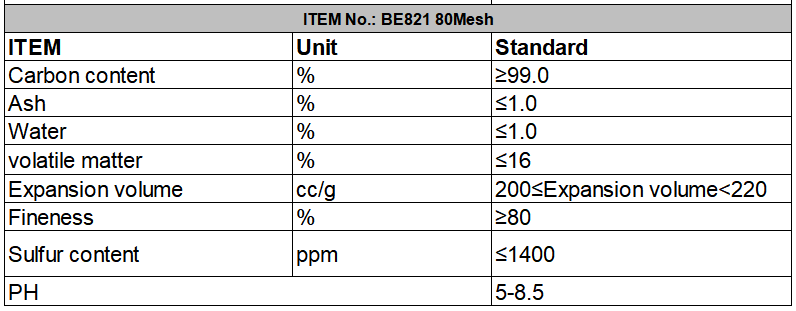

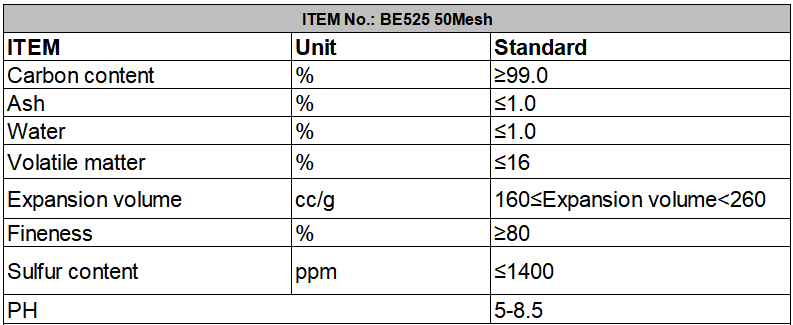

Expandable graphite is produced through a process of subjecting flake graphite to high temperature treatment. This versatile material has a wide range of applications, including its use in the production of graphite paper, fireproof adhesive tape, and for sealing purposes in various industries, such as the battery industry. Different specifications of expanded graphite are available, ranging from 50 mesh to 200 mesh, with expansion ratios that can vary from 100 times to 300 times.

The expansion of graphite is due to the release of gas molecules, which are trapped within the graphite layers as a result of the chemical treatment. As the temperature increases, the gas molecules are released and cause the material to expand. The expansion can be controlled by adjusting the chemical treatment process, which affects the size and number of gas molecules trapped within the graphite layers.

Expandable graphite has several industrial applications, including as a flame retardant in plastics, as a thermal insulation material, and as a material for producing graphite foams. Its ability to expand and form a protective layer also makes it useful in fire protection systems, such as fire-resistant coatings and fire doors.

mobile phone+86 18562598641