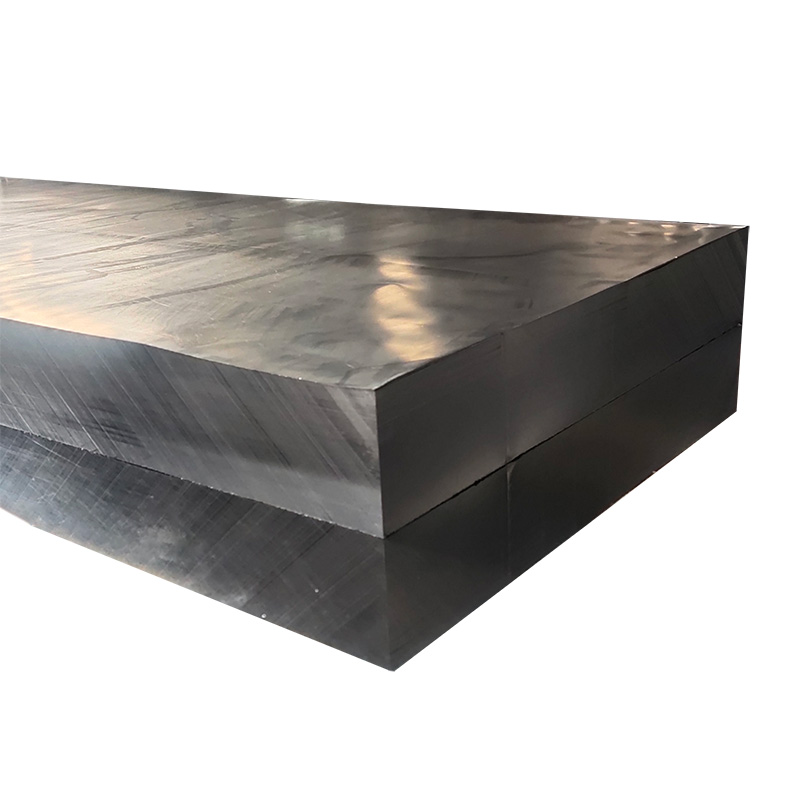

Flexible graphite sheet is a highly versatile material that has a wide range of applications across various industries. It is a type of graphite material that is made by compressing and rolling graphite flakes into a thin sheet, which is then reinforced with a metallic or non-metallic core. The resulting material is highly flexible, durable, and has excellent thermal and electrical conductivity properties. In this article, we will discuss the properties and applications of flexible graphite sheet in detail.

Properties of Flexible Graphite Sheet

Flexible graphite sheet has several unique properties that make it an ideal material for various applications. Here are some of the key properties of flexible graphite sheet:

Flexibility - As the name suggests, flexible graphite sheet is highly flexible and can be easily molded into different shapes and sizes. It can bend and conform to complex shapes without cracking or breaking, making it ideal for use in tight spaces or complex geometries.

Thermal Conductivity - Flexible graphite sheet has excellent thermal conductivity properties, which makes it ideal for use in high-temperature applications. It can withstand temperatures up to 4000°F (2200°C) and has a low thermal expansion coefficient, which ensures that it maintains its shape and properties even at high temperatures.

Electrical Conductivity - Flexible graphite sheet is also an excellent electrical conductor, which makes it ideal for use in applications that require high levels of electrical conductivity. It has a low electrical resistance, which means that it can carry large currents without overheating or breaking down.

Chemical Resistance - Flexible graphite sheet is highly resistant to chemical attack and can withstand exposure to a wide range of chemicals and solvents. This makes it an ideal material for use in harsh chemical environments, such as those found in the petrochemical and pharmaceutical industries.

Applications of Flexible Graphite Sheet

Flexible graphite sheet has a wide range of applications across various industries. Here are some of the key applications of flexible graphite sheet:

Heat Shields - Flexible graphite sheet is often used as a heat shield in high-temperature applications. It can be used to insulate pipes, furnaces, and other equipment that generates heat, helping to prevent heat loss and improve energy efficiency.

Gaskets - Flexible graphite sheet is also commonly used as a gasket material. Its flexibility and ability to conform to complex shapes make it ideal for use in sealing applications, such as in engines, pumps, and valves.

Electrical Contacts - Flexible graphite sheet is an excellent electrical conductor, which makes it ideal for use in electrical contacts. It can be used to make brushes, slip rings, and other components that require high levels of electrical conductivity.

Corrosion Protection - Flexible graphite sheet can be used as a barrier material to protect against corrosion. It can be applied as a coating or wrapped around equipment to prevent corrosion from occurring.

Thermal Insulation - Flexible graphite sheet can also be used as a thermal insulator. Its high thermal conductivity properties make it ideal for use in insulating walls, roofs, and other building components, helping to improve energy efficiency and reduce heating and cooling costs.

Conclusion

Flexible graphite sheet is a highly versatile material that has a wide range of applications across various industries. Its unique properties, such as flexibility, thermal conductivity, electrical conductivity, and chemical resistance, make it an ideal material for use in high-temperature, harsh chemical, and electrical applications. Whether you need a heat shield, a gasket, an electrical contact, or a thermal insulator, flexible graphite sheet can provide the performance and durability you need.

mobile phone+86 18562598641